Industry report

How To Stay Ahead Of The Automation Trend? – An Industry Research

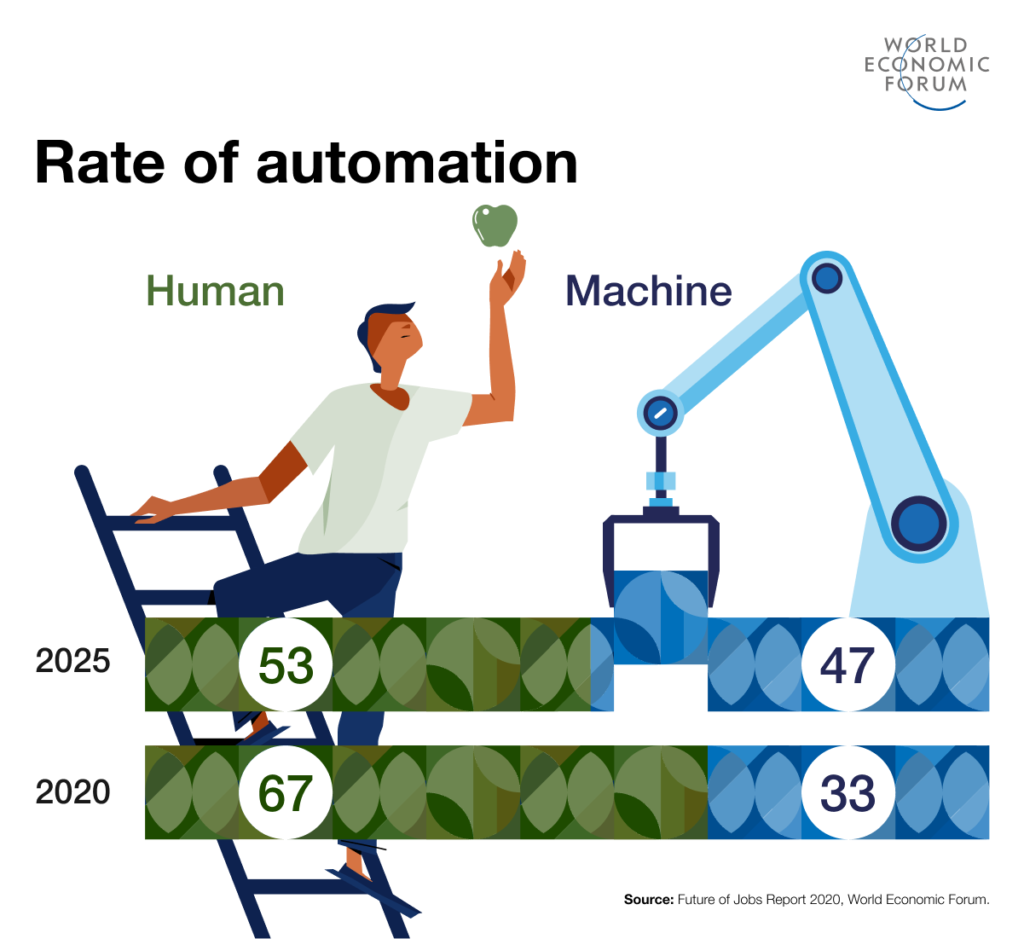

The automation of labour with robots is inevitable. It is speculated that by 2025, the latest industrial automation revolution will result in nearly half of the workforce being replaced by machines and process control. New career path opportunities are emerging to replace the obsolete manual jobs of the past, pushing the education sector to transform in order to remain relevant.

This article exposes you to the interconnectedness of the economy of industrial automation, the job landscape, and the education system as well as their past, current, and future developments.

Automation has become a dominant global force across all industries and engineering disciplines. Whether you are diligent educators, students, or professionals, it is critical to stay on top of international market trends. Understand the direction the industry is heading gives you the power to make acute decisions for your students and your career development.

Key points:

- The meteoric rise of industrial automation technologies leads to a giant and lucrative global market worth hundred of billions now and more in the near future.

- With the market booming, demand for automation specialist is increasing every year. Obsolete jobs, however, are being replaced by digitalized process.

- Multiple options for students to gain experiences and break into the industrial automation field. Education providers & instructors have to adapt and transform to new challenges to keep up with the international trends, especially in delivering sufficient practical projects to students

Industrial automation – THE FUTURE IS NOW!

The field of industrial automation has transformed from an emergent technology to a colossal and lucrative industry, as we see today. Numerous reports have predicted its market size will reach at least $USD 370 billion by 2027; doubling from an already impressive $USD 190 billion in 2017.

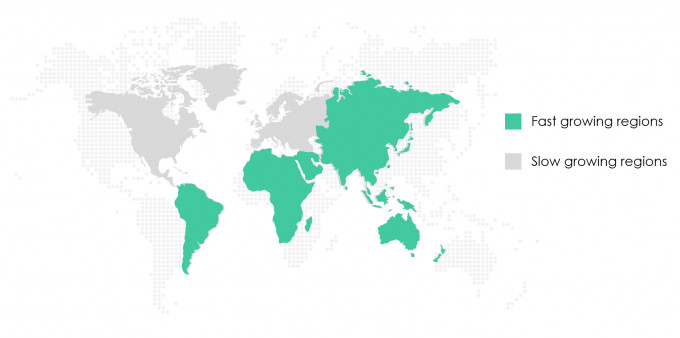

The Asia Pacific (APAC) was the market leader in 2020 thanks to its immense scale of the manufacturing sector. Europe and North America held the remaining top spots. In addition, China, Japan, and South Korea, are both the largest producers and consumers of industry technologies.

So, what are the reasons for this significant boom of automation? Researches have pointed out 3 prominent driving forces:

1. The modern industrial revolution – Industry 4.0 (or Internet of Things) transforms the digital supply chain across industries. Furthermore, new Industries 5G wireless technologies speed up our capability of multi-process control which vastly optimize production cost and lead the way for future digital disruptions. Honeywell International, Inc., Tech Mahindra Limited and ABB Ltd are some of the main players who are capitalising on these technologies to expand their global market.

2. The transformation of global manufacturing technology from manual to fully automated.

3. Favourable government policies incentivising digitalization to further diversify emerging markets within the industries of transportation, healthcare, retail.

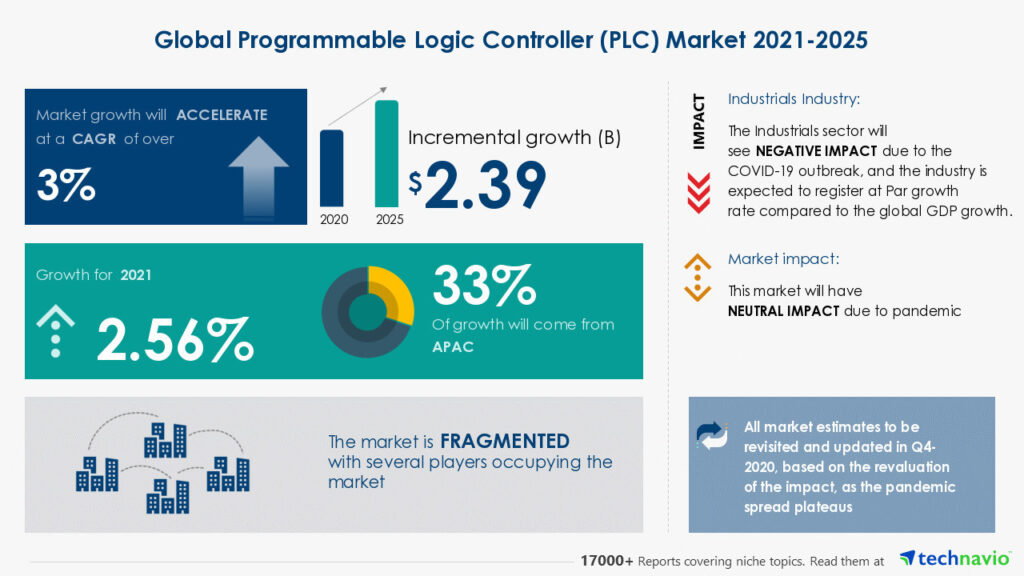

The market for PLC is also booming following the surge in industrial automation adoption. The APAC region, again, dominates the global market. In terms of performance, however, South America takes the first spot for the duration of 2019 – 2024.

Demands for PLC in plant-level control has developed significantly thanks to:

1. The urgent demand for compact and robust automation solutions from the global market. Innovations in renewable power generation also have found their way be more efficient through automation technology thus boosting the market for PLCs

2. Smaller sized circuit boards, semiconductors, electric components enable PLCs to be more compact with a faster processor, better memory, and new communication features.

3. PLC customization ability is key. Clients are becoming increasingly more specific in their needs of automation processes design. Tailor-made PLCs have become more ubiquitous since they can solve specific problems such as plant space limitation, environmental operating conditions, and process complexity.

Automation specialists will lead the future of jobs

While the industrial automation expansion showing no sign of slowing down, one major challenge that hinders its growth is the lack of technical expertise in the field. The demand for experience in automation technologies has skyrocketed during the past decade and is becoming the deciding factor in determining one’s future employment prospects.

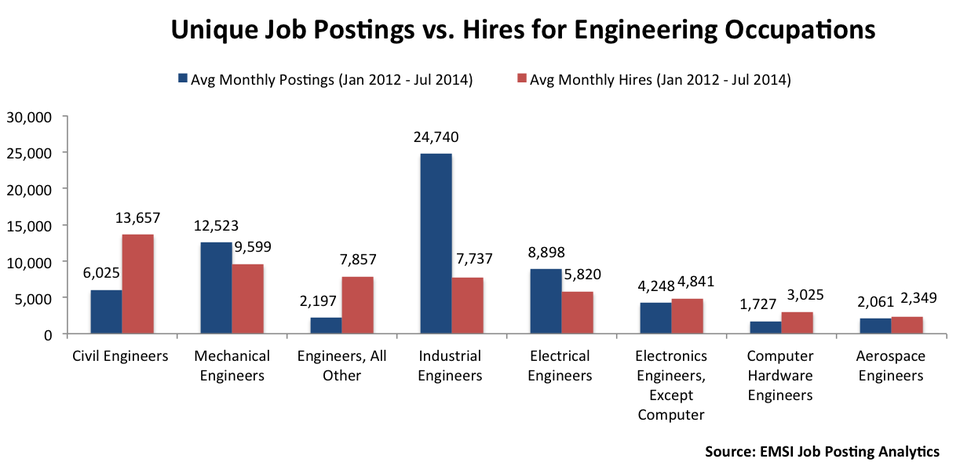

We can observe this meteoric rise by looking through the job market data trends from 2012 to future predictions in 2025.

Data in the 2012-2014 period showed that demand for industrial engineers in the USA was a tower above all other engineering disciplines. With nearly 25,000 job posts every month, it doubled the number of job posts for mechanical engineers – the next highest discipline. However, when we look at the actual monthly hires, only 1 out 3 posts managed to find a suitable candidate. This phenomenon signifies the major shortage of relevant automation experience in the labour pool, which was unable to keep up with the employer’s demands. This is typical of new industries; when the technology has innovated beyond the current labour capability.

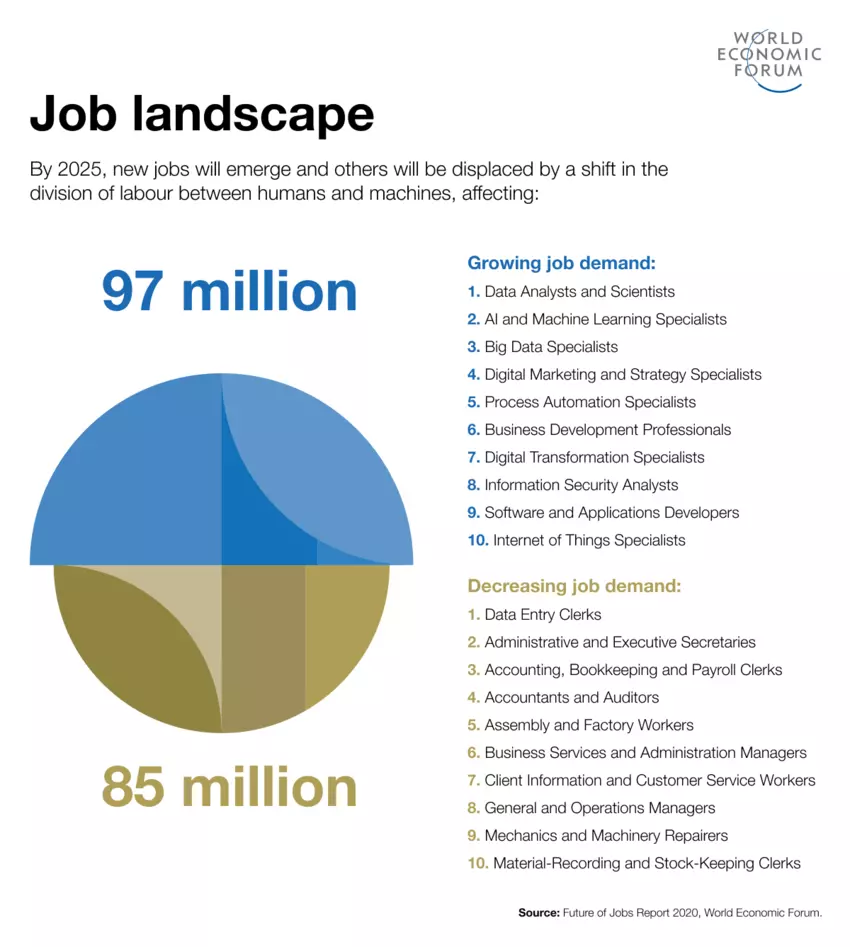

As expected, this trend continues into our current time and the next decade. World Economic Forum predicted that by 2025, positions in process automation, digital transformation, IoT, and robotics will dominate the job market.

On the other hand, the labour shift from humans to machines will leave data entry employees, assembly factory workers, and operation managers mostly redundant. This means around 85 million employees globally must either upskill or change their career to fit into the new digital & automation era, else they will risk being replaced by future technologies.

Looking at a national scale, the engineer job market in Australia (a member of APAC) attested to this development in 2019. Industrial, Mechanical and Production Engineers have consistently ranked amongst the top 3 in-demand vacancies.

Multiple global industry reports also confirm the absolute dominance of automation & robotics engineers amongst the top sought-after disciplines.

In addition, data on popular jobs websites like payscale.com and indeed.com shows that expertise with PLCs is fundamental for roles such as Control Systems Engineer, Electrical Engineer, and Automation Engineer.

In short, the current and future job market has its door wide-open for automation specialists. Whether you are an academic, tech professional, or aspiring student, experience in industrial automation, process control and PLC systems will bolster your career prospects for many years to come.

Automation & PLC training courses are booming

So how can one break into the field of industrial automation? Fortunately for us, the rise in job market demand has translated well into the education sector. What we are witnessing is the start of a surge in automation and robotics training programs in a variety of shapes and forms on an international level.

Online training courses are the quickest to catch onto the trend. A quick search on Udemy will return hundreds of courses on PLC training.

While this is the easiest and cheapest learning option, they provide limited practical and hands-on experience, questionable standardisation or certification, and little to no personal interaction.

Most courses also only focus on the PLC programming languages. Although this is a fundamental skill, learning how to use PLCs requires much more than just knowing how to write the code. Laboratory exercises are an integral part of industrial automation training. However, these online courses are excellent if you need a quick introduction or a short refresher on conceptual knowledge.

On the opposite spectrum, a bachelor or master degree will provide you with a more complete training pathway. In exchange, it is the most time consuming and expensive option both for educators and students.

Due to the massive R&D cost and investment risk, only some global universities & institutes have developed a complete course on industrial automation. Here in Australia, the University of Sydney, University of Western Australia, and Engineering Institute of Technology are amongst the few higher education providers that have successfully introduced full degrees in automation, manufacturing, and robotics in recent years.

For the remaining providers, instead of developing a completely new course on automation, they have opted to introduce one or several units on the topic of PLCs, SCADA, and HMIs, etc.

These units become integrated into the existing engineering degrees (mechanical, electrical) or became electives.

This strategy proves to be more popular since it allows the organization to “test the waters” before committing to a full course; able to capitalize on the trend but at a much lower cost. Prominent names using strategy include the University of South Africa, University of Sussex (UK), Purdue University (USA), RMIT (Australia) and many more.

The vocational education sector, meanwhile, provides an ideal model for automation training.

With less pressure to uphold a prestigious reputation of a high-education provider, they have more freedom in designing their course offerings to suit the immediate demands of the industry.

Vocational PLC training courses can range anywhere from 3 months to just a few days.

While these courses have a smaller scope than those of universities, they provide a sharper focus on the topic centralized around hands-on exercises in an apprenticeship environment – one of the major losses for online courses.

The main challenge for these organizations, however, is the high cost of laboratory investment, which consists of hardware costs, hosting, time, and human resources.

Regardless of what type of education structure you belong to, one must accept the current reality of the job market; companies can no longer spend months on training new graduates. Instead, graduates are now expected to be capable in their roles after just a few weeks.

For educators, it is a challenge to ensure a comprehensive, current and industry-relevant learning program with sufficient practical exercises, within a limited budget. This requires being cognizant of the market and the relationship between the current and future in-demand- jobs and training requirements.

Modern students need to be job-ready, even before they leave the institution.

Related news:

Technical

What Is PLC? Simple PLC Concepts Explained

PLC or Programmable Logic Controller is the building block of industrial automation. Quickly learn simple...

Technical

What Is A PLC Made Of? Basic PLC Hardware Guide

Learn the basic hardware that makes up a PLC using your personal computer as a...