Technical

What Is PLC? Simple PLC Concepts Explained

PLC means Programmable Logic Controller. It is one of the most essential building blocks of industrial automation. A PLC functions as a robust and easy-to-program industrial computer, used to control a wide range of plant processes.

Why PLC technology has become a key global market driver:

- It is flexible and scalable to fit in multiple industrial projects from simple to complex thanks to its modular design, and available instruction sets following international standards.

- It has a robust and solid-state build with no moving parts to ensure control stability under harsh conditions.

- It requires simpler wiring compared to traditional relay networks while also achieve achieving faster response times which mitigates risks and improves cost optimization.

Key points:

- Programmable Logic Controller (PLC) is an important part of plant process

- As an “industrial computer”, PLC provides a safer, more flexible and cost effective solution to the automation industry

- The global automation transformation has put PLC as the forefront. Experience in PLC system is hugely advantageous for future engineers and technicians.

In the beginning, processes were manually controlled through human labour; for example, windmills and waterwheels, or the Mayans water transportation system via aqueducts. The industrial revolution then brought in massive mechanical production/ assembly lines functioned by factory workers; Charlie Chaplin’s Mordern Times provides a humorous yet true depiction of technologies in this era which underscores the need for a safer automation process.

Surely there has to be a better and safer method, Mr. Tramp! – Source: giphy

A significant automation improvement came with the introduction of electromechanical relays. However, even this type of technology has become rigid and dangerous in modern days due to the risk of excessive human interactions in complex projects. Thus, the quest for a more robust and more flexible system with less human involvement resulted in the invention of PLC in 1964 by Dick Morley.

In a hard-wired relay-based system, a small change in control logic leads to a colossal re-wiring project that is costly, time inefficient, and vulnerable to serious errors. Faults in the automation process have the potential to cause serious damage to equipment and operators.

Since PLC is “digitally programmable” through coding, the process control logic can be programmed, troubleshooted, reprogrammed to specific designs using simplified and standardized programming languages, such as ladder logic.

These programs then can be instantly shared, verified, and implemented amongst PLC specialists in a matter of minutes, further decreasing cost and operational complexity.

The main benefit of PLCs, however, is it ensures safety and stability for the entire process with the ability to test, and debug the program effectively before deployment. It paved the way for modern technologies to replace the physical labour with automation applications. In short, the PLC has transformed industrial automation into a smarter, safer, and richer future.

PLC provides us a cleaner, safer, and more efficient production technology – Source: primogif

PLC – a robust PC built for industry

We can think of PLC as a PC since they are both built from similar components: CPU (Central Processing Unit), internal & external memory, input and output modules (I/O), power supply, and protective chassis.

They are also controlled by their specific operating software; for PC, this means Windows, Mac, or Linux; for PLC, this means SIMATIC STEP 7 for Siemens PLC, RSLogix series for Allen Bradley’s and so on.

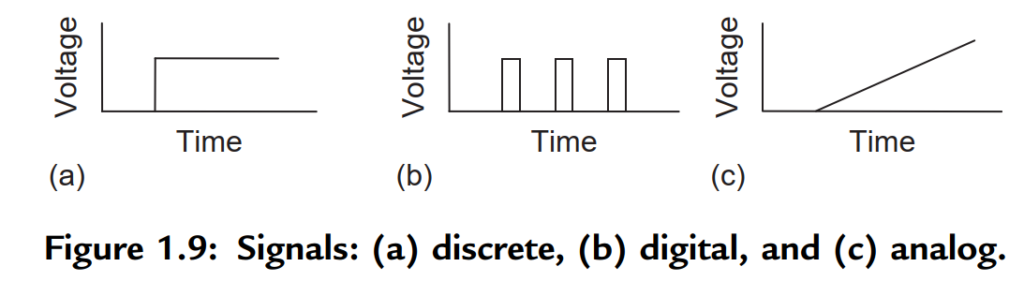

However, while a standard PC can be a delicate piece of equipment, PLC is designed to be industrial-grade: capable to function under severe industrial conditions: extreme temperature, moisture, dust, etc. Furthermore, it can also execute both discrete and continuous signals, unlike an ordinary PC.

How to prepare for the global automation and PLC transformation

Nowadays, you can find PLC to be omnipresent in modern engineer projects and facilities: manufacturing factories, production plants, assembly lines, and beyond.

The intelligent automation trend has created an influx of demand for automation specialists, thus a myriad new course in industrial automation and robotics has emerged robustly in the past years. Universities, colleges, vocational institutes across the globe are racing to update their training scheme to ensure students have acquired skills for the future of the industry.

Various STEM courses such as mechanical engineering, electrical and electronic engineering have incorporated knowledge on PLC, SCADA, and industrial automation into their curriculums and learning outcomes.

SIEMENS PLC. PLC can replace most of human interaction within an automation process – Source: Siemens

Many educators, however, have to deal with numerous challenges in implementing a practical PLCs training program, such as cost and availability of lab equipment, limited lab time and space, lab learning outcomes that do not fulfil its course’s curriculum, etc.

It is critical that students receive lots of relevant practical experiences to understand the operation of and to program, test, and debug a PLC system efficiently.

Furthermore, to maintain student engagement, teachers need to provide them with interesting, and challenging hands-on exercises, and real-life case studies.

Understanding these frustrating difficulties you are facing, we decided to develop our Complete Automation Training Solution (CATS) to be a comprehensive, affordable, and flexible solution to industrial automation practical education.

CATS is designed for educators and instructors regardless of your backgrounds to empower you to provide quality training to your students, globally.

LEARN MORE: PART 2 – BASIC PLC HARDWARE

Bibliography

W Bolton, Programmable Logic Controllers. Burlington, Ma Newnes/Elsevier, 2016.

IDC Technologies, Fundamentals of Instrumentation, Process Control, PLCs and SCADA for Plant Operators and Other Non-Instrument Personnel, 5th ed. IDC Technologies, 2011.

Related news:

Industry report

How To Stay Ahead Of The Automation Trend? – An Industry Research

Automated labor is inevitable. Learn how industrial automation is changing the job landscape and training...

Learn moreTechnical

What Is A PLC Made Of? Basic PLC Hardware Guide

Learn the basic hardware that makes up a PLC using your personal computer as a...

Learn more